Picture this: You’ve just unboxed a high-end electronic device, and the first thing you notice is the flawless finish. Color coating plays a pivotal role in this first impression, elevating aesthetics and providing functional benefits. However, why do failures always occur during the coating process? What if you could achieve a flawless finish while enhancing durability and sustainability? This is where advancements in color coating technology come into play.

Traditional Solution Flaws

Traditional coating methods have long been plagued by issues such as inconsistent coverage and VOC emissions. Common applications often lead to uneven finishes, compromising the final product’s appearance and longevity. This inconsistency can significantly impact user satisfaction and brand reputation—something every manufacturer should avoid. Moreover, the environmental implications of these older techniques become a focal concern in today’s standards, driving the industry toward more sustainable alternatives.

New Technology Principles

Enter modern color coating technologies that promise greater precision and eco-friendliness. Techniques such as electrostatic spray coating and powder coating are gaining traction. These innovative methods utilize charged particles to ensure a uniform coat, which not only improves appearance but also reduces waste. Plus, advancements in biocompatibility mean that coatings are now safer for both users and the environment. It’s simpler than you think—techniques have evolved to address the shortcomings of their predecessors.

Quantified User Benefits

Implementing these new technologies offers measurable benefits. Users report increased satisfaction due to the superior aesthetic and durable finishes—think less wear and improved longevity of products. Manufacturers can save costs on rework and materials while enhancing their brand’s image with eco-friendly practices. Always verify these 3 metrics when choosing solutions: ① durability ② environmental impact ③ aesthetic quality. The adoption of these criteria will propel your projects toward success.

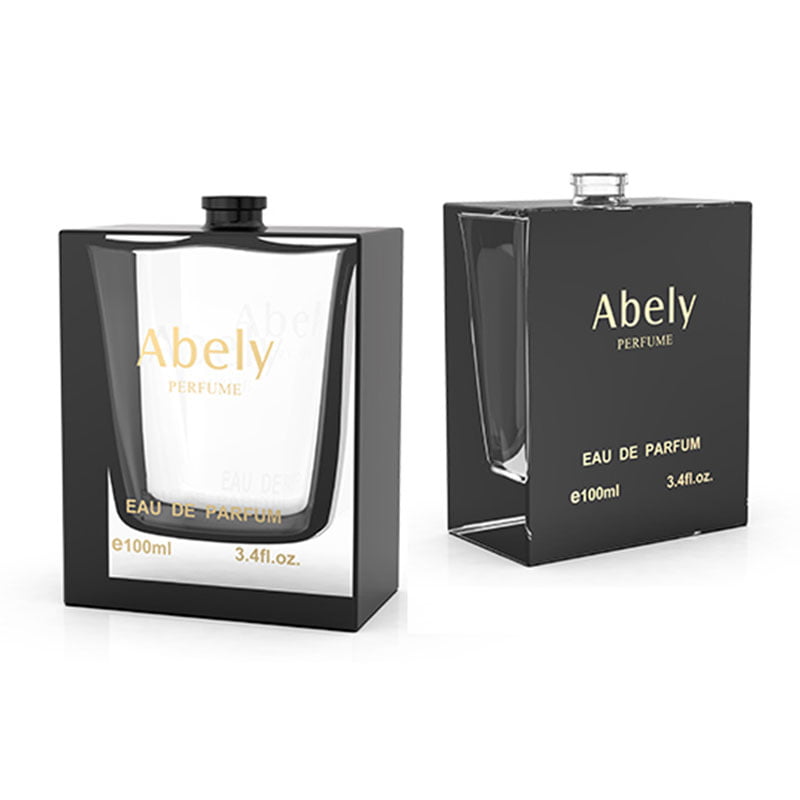

Design for Perfume Bottle Packaging

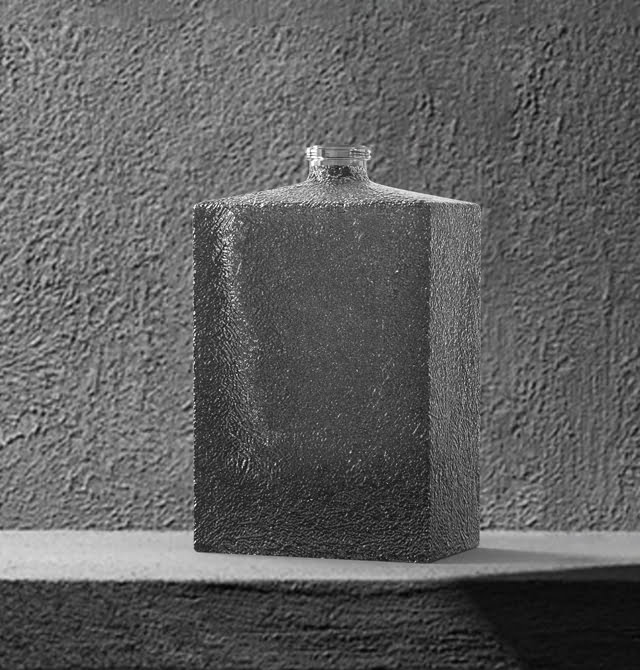

The aesthetics of a product are just as crucial as its functionality, especially in the fragrance industry. When it comes to perfume bottle packaging design, the character of the bottle can significantly influence consumer perception. A visually appealing bottle that incorporates innovative materials can attract customers and enhance the brand message. Moreover, using color coating in packaging design not only adds visual flair but also ensures that the bottle remains resistant to scratches and wear.

Advanced Approaches in Packaging Design for Perfume Bottle

Exploring advanced techniques for design for perfume bottle can elevate a brand’s standing in a competitive market. Utilizing modern approaches allows designers to create captivating and functional packaging that ensures product integrity while catching the consumer’s eye. Added features, such as textured surfaces and unique finishes through innovative color coating, provide tactile engagement that enhances customer satisfaction. Ultimately, this blend of form and function is crucial for success in the luxury fragrance market.

In conclusion, embracing innovations in color coating not only enhances the visual appeal of products but also boosts functionality and sustainability. By prioritizing factors such as durability, aesthetic quality, and environmental impact, manufacturers can elevate their brand image and customer satisfaction. For those seeking reliable and advanced solutions, look no further than Abely, a manufacturer recognized for its supply advantages and market expertise in color coating technologies.