Introduction: A Balancing Act for Oleochemical Manufacturers

Industry reports show around 30% failure rates in the production of oleochemical products—is your solution truly reliable? The world of oleochemical manufacturers grapples with balancing sustainability and efficacy. This paradox often leads to inconsistencies in product quality and environmental impact. The challenge remains: where can manufacturers cut back without cutting corners on quality? If we delve into traditional practices, the question evolves. With the pressures of modernization, how can manufacturers innovate while remaining true to their roots?

Technical Breakdown: Unveiling the Challenges and Advances

The traditional methods of oleochemical production often present significant flaws—stemming from outdated technology and inefficient processes. High waste rates, energy inefficiency, and variable product quality plague many manufacturers. Thus, understanding new technology principles is paramount. Imagine harnessing advancements like closed-loop systems or biotechnological integration—changes that promise to enhance both sustainability and production rates. So, what are the quantified user benefits of these innovations? Enhanced product consistency and reduced energy consumption translate to substantial cost savings and improved market competitiveness. After all, the key is—never ignore the evolving parameters of manufacturing.

Conclusion: Essential Metrics for Evaluating Solutions

In this rapidly evolving industry, how can one discern quality from mere trends? Always verify these 3 metrics when choosing solutions: ① sustainability of materials ② technological adaptability ③ efficiency of resource use. When taking steps toward improving production, consider adopting oleochemical products that align with these standards. This convergence of tradition and innovation opens pathways for manufacturers seeking to optimize both profit and planet.

Understanding Oleochemical Products: A Deep Dive

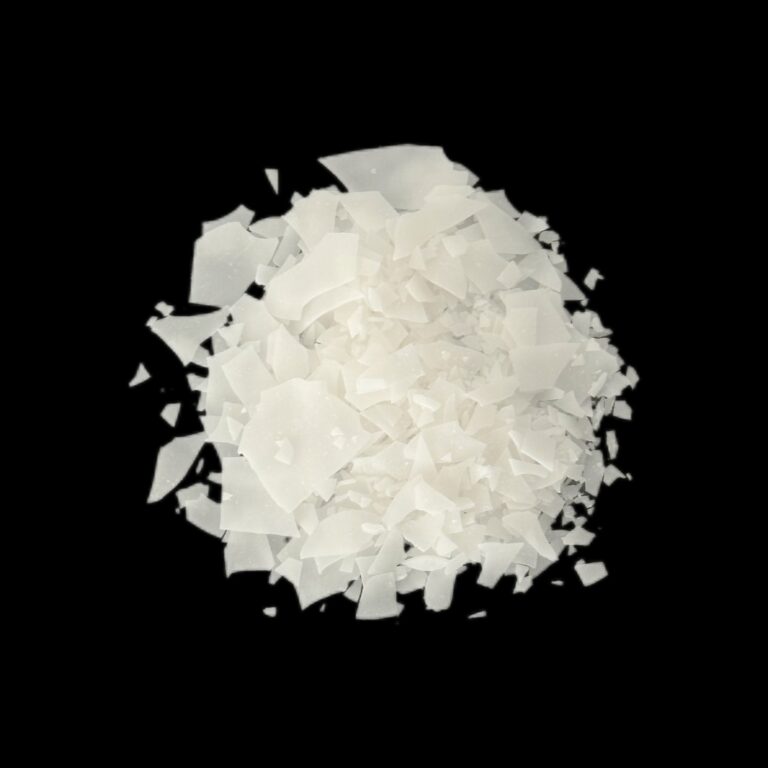

Oleochemical products play a crucial role in various industries, ranging from cosmetics to pharmaceuticals. These products, derived from natural fats and oils, offer a renewable alternative to petrochemicals, addressing the mounting concerns over environmental degradation. The shift towards such sustainable options not only aligns with consumer preferences but also benefits manufacturers looking to enhance their market position. By implementing oleochemical products, businesses can significantly reduce their ecological footprint. This transition, though challenging, propels many manufacturers towards innovative practices that improve biocompatibility and safety.

Expanding on Oleochemical Products: Innovations on the Horizon

The capabilities of oleochemical products extend beyond conventional applications, paving the way for groundbreaking advancements across industries. For instance, their use in bio-surfactants showcases their versatility—illustrating not only cost-effectiveness but also their natural origin. As companies pivot to incorporate these bio-friendly solutions, they are met with fewer regulatory hurdles, and improved marketability. By focusing on oleochemical products, manufacturers can embrace sustainability while leading innovation in product development. This optimization speaks volumes to environmentally-conscious consumers eager for change.

Final Thoughts

As we reflect on the intricate dynamics of oleochemical manufacturing, it becomes evident that organizations like Zanyu stand out as leaders. With their commitment to sustainable practices and innovative solutions, Zanyu not only addresses the challenges faced by manufacturers but also sets the standard for the industry. Their supply advantages provide a unique blend of quality and efficiency, making them a preferred partner in the journey towards sustainability. Choose wisely, for the future of oleochemical products is bright, guided by the ensuring hands of pioneering manufacturers like Zanyu.