PVC hoses have become the backbone of numerous industries, providing unmatched flexibility, durability, and versatility for various applications. From agriculture to chemical processing, construction to food and beverage industries, PVC HOSE Manufacturer are often the go-to solution for transporting liquids, gases, and semi-solid materials. But what makes PVC hoses the first choice for so many industries? In this article, we’ll explore the unique benefits of PVC hoses and why they continue to be a critical component in industrial operations worldwide.

1. Unmatched Flexibility

One of the standout features of PVC hoses is their flexibility. This characteristic allows them to easily adapt to a wide range of environments, making installation and operation smoother. Whether you need to transport fluids through tight spaces or navigate complex piping systems, PVC hoses can be maneuvered to fit the requirements without compromising their performance.

Flexible hoses are particularly useful in industries like agriculture and irrigation, where hoses must often be laid out over long distances and in various terrains. The ability to bend, twist, and coil these hoses without damage makes them a preferred option for industries where adaptability is key.

Moreover, flexibility doesn’t mean fragility. PVC hoses maintain their shape and function even after being exposed to constant bending, pressure, or changes in environmental conditions, ensuring longevity and consistent performance.

2. Durability and Long Service Life

Durability is another factor that puts PVC hoses at the top of the list for industrial applications. These hoses are designed to resist wear and tear even in challenging environments. They are tough enough to withstand exposure to harsh chemicals, extreme temperatures, UV radiation, and physical abrasion.

Industries such as construction and mining, where hoses are exposed to rough handling and heavy equipment, often turn to PVC hoses for their ability to resist damage from abrasion or impact. Even in outdoor settings, where hoses are subjected to weather fluctuations, PVC hoses remain intact and functional for extended periods, reducing the need for frequent replacements and minimizing operational costs.

The reinforced layers in many PVC hoses add an extra layer of protection. For instance, fiber-reinforced or steel-wire-reinforced PVC hoses are designed to handle higher pressures and resist kinking or collapsing. This reinforcement ensures that the hoses perform well even under high-stress conditions, such as in hydraulic systems or industrial vacuum applications.

3. Chemical and Corrosion Resistance

One of the main reasons PVC hoses are favored in industries like chemical processing, water treatment, and food and beverage is their excellent resistance to a wide range of chemicals. PVC material is inherently resistant to most acids, alkalis, salts, and oils, making it an ideal choice for transferring fluids in environments where chemical exposure is common.

Unlike rubber hoses, which may degrade when exposed to certain chemicals, PVC hoses remain unaffected, ensuring safe and reliable fluid transfer. This chemical resistance extends the lifespan of the hose and maintains the integrity of the transported materials, which is especially crucial in industries where contamination is a serious concern.

Additionally, PVC hoses are highly resistant to corrosion, making them suitable for applications in wet or humid environments, such as marine industries or wastewater management systems. Corrosion-resistant hoses reduce maintenance efforts, prevent leaks, and ensure a cleaner, safer operation overall.

4. Cost-Effective Solution

PVC hoses are not only highly functional but also cost-effective. Compared to hoses made from rubber, metal, or other polymers, PVC hoses offer a more affordable solution without compromising on performance. Their long service life and minimal maintenance requirements make them a cost-effective choice in the long run, especially in industries with high operational demands.

Because of their affordability, PVC hoses are widely used in applications where hoses need to be replaced frequently or installed over large areas, such as in irrigation systems, temporary construction sites, or industrial cleaning operations. The combination of lower initial costs and reduced replacement frequency makes PVC hoses a smart investment for businesses looking to optimize their operational expenses.

5. Versatility for Various Applications

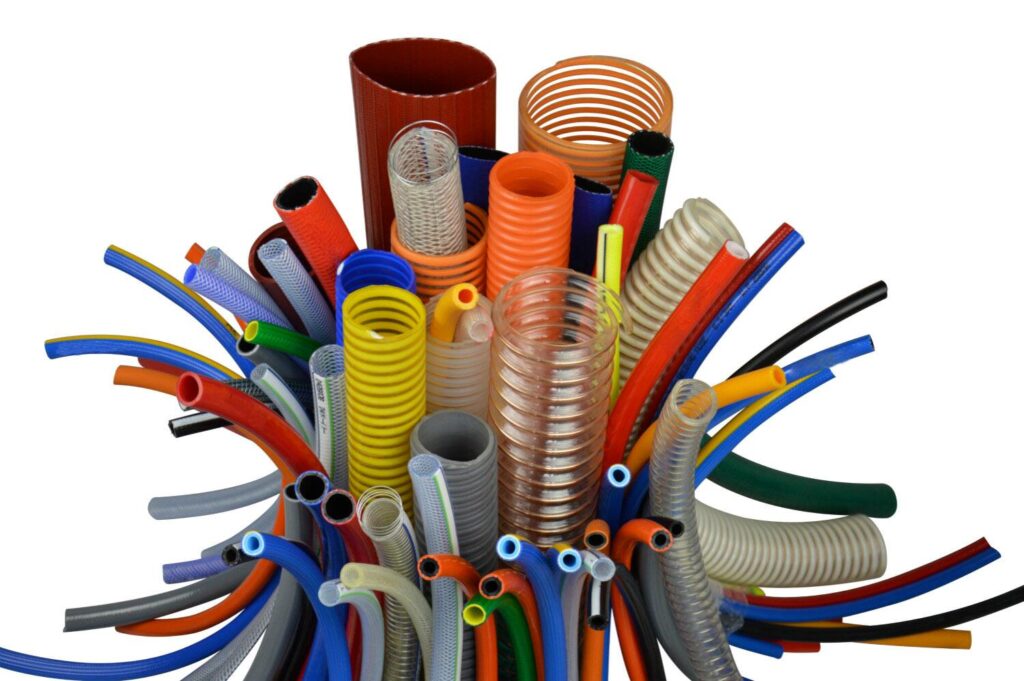

The versatility of PVC hoses is another key reason why they are the first choice for many industries. PVC hoses are available in a wide variety of types, sizes, and configurations to meet the unique demands of different applications. Whether you need a lightweight hose for air or water transfer, a reinforced hose for high-pressure systems, or a food-grade hose for sanitary applications, there is a PVC hose designed for the job.

For instance:

- Clear PVC hoses are often used in food and beverage industries for visual inspection of fluids, ensuring cleanliness and transparency.

- Suction and discharge hoses are widely used in agriculture and construction for water transfer, debris removal, or material handling.

- Chemical-resistant PVC hoses are ideal for laboratories, chemical plants, and industries dealing with hazardous materials.

The ability to customize PVC hoses for specific applications, from color coding to specialized reinforcements, further adds to their versatility, ensuring that businesses can find the exact hose that fits their operational requirements.

6. Lightweight and Easy to Handle

PVC hoses are significantly lighter than rubber or metal hoses, making them much easier to handle and install. This lightweight nature is a major advantage, especially in applications where hoses need to be moved frequently or laid out over long distances.

In industries like agriculture, where hoses are often transported across fields or connected to mobile irrigation systems, lightweight PVC hoses reduce the physical strain on workers and equipment, leading to faster installation and reduced labor costs. Similarly, in automotive and industrial cleaning applications, lightweight hoses improve maneuverability, making tasks like washing, cleaning, and vacuuming more efficient.

7. Eco-Friendly Options

With growing awareness about sustainability and environmental impact, the demand for eco-friendly industrial products has risen. Many PVC hose manufacturers are stepping up to offer greener alternatives by incorporating recycled materials and ensuring that their products are fully recyclable at the end of their life cycle.

Eco-friendly PVC hoses contribute to the reduction of industrial waste and the overall environmental footprint of businesses. This is especially important in industries that prioritize sustainability, such as organic farming or green construction projects.

Conclusion: The Reliable Choice for Modern Industries

PVC hoses have earned their place as the first choice for many industries, thanks to their flexibility, durability, chemical resistance, cost-effectiveness, and versatility. Whether you’re working in agriculture, construction, food processing, or chemical handling, PVC hoses offer the right balance of performance and affordability to meet your needs.

As industrial demands evolve, PVC HOSE Manufacturer continue to adapt through innovation in materials, design, and manufacturing processes. This ensures that they remain a reliable and indispensable tool for businesses looking to operate efficiently and effectively in today’s fast-paced industrial environment.